| What's Hot! | Products/ Tools | EFI Tuning | Basic Tuning | Advanced Tuning | Chassis Tuning | Advertise with us |

A closer look at Direct Injection for fueling Gas and Diesel Motors

The advantages + Disadvantages of direct injection

Contributed by: Enginebasics.com

Direct injection is a new technology that is finding its way onto many of the new gasoline and diesel engines that are coming to market. Many of us do not understand how this type of injection differs to what we have always had on EFI fuel systems. The goal of this article is to explain the difference between standard port fuel injection and direct injection.

What is Direct Injection?

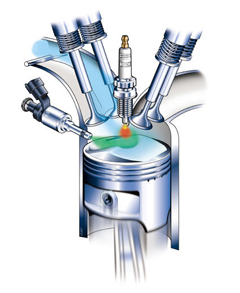

Direct injection is just as the name implies. It’s fuel that’s DIRECTLY INJECTED into the combustion chamber. This is made possible by fuel injectors that work at injection pressures of around 2,000 psi. Sounds unreal right? Remember that while you may have a static cylinder pressure between 100 psi and 300 psi, depending on the compression of the motor, during actual combustion cylinder pressures spike to much higher levels. To be able to then inject fuel into this high-pressure environment, an even higher-pressure fuel injector must be used. This gives us the ability to inject fuel directly into the cylinders high-pressure environment at any time during the engine cycle.

What is Port Injection?

Port injection is when the fuel is injected prior to entering the cylinder in the intake manifold ports. This type of injection relies on an injection of fuel at pressures between 40 psi and 80 psi. The fuel pressure regulator controls the pressure of the fuel injector. The velocity of the intake port air as well as port shape and spray pattern of the fuel injector are all very important in making a port injection system function properly.

What are the benefits of Direct Injection on Diesel and Gasoline motors?

There are many benefits to direct injection, but we will just focus on the more important ones:

1. Cooling of combustion temperatures. Because the fuel can be directly injected into the combustion chamber you get a far greater cooling effect as the fuel atomizes and changes from a liquid to a gas under the forces of compression.

2. The ability to control the injection during the combustion cycle. While all of the fuel used in the combustion process is injected in a port injection type setup, Direct Injection can inject measured amounts of fuel DURING the combustion cycle to aid in the burn cycle and flame propagation through the firing stroke.

3. Greater control of avoiding detonation and pre-ignition. Because of the ability to control the timing of the injection of fuel into the combustion chamber, like we talked about in number two above, we can also use that control to avoid pre-ignition and detonation. On current EFI equipped set-ups we have always used ignition timing to control the burn sequence, but with direct injection we now have another option of control.

Now this is not the entire list of benefits that can be had from direct injection, but it is a good start at the major ones. Getting into the other benefits about emissions and quieter diesel operation we will not get into.

Downsides to direct injection

Like any new technology, it’s expensive. Hopefully you will never have to replace one of these injectors because they can be 5X-10X the cost of a standard fuel injector. While this price discrepancy will slowly disappear as this technology becomes more and more common, for now it needs to be addressed. Other than the cost, there are no real downsides. What will be interesting to see is if some short falls are discovered as the aftermarket scene will start to push these direct injection motors and injectors past there limits.

In a discussion on direct injection with another engineer the follow was written:

"For those not familiar, direct injection puts the injector nozzle in the combustion chamber, similar to how a diesel runs. A diesel relies heavily on injector timing to control combustion and a glow plug to make sure there is something to start the flame front in the chamber. Direct injection also relies on injector timing, but maintains the spark plug to actually light the mixture and control combustion. The injectors must operate at extremely high pressures as combustion pressures can exceed 2000psi and the fuel has to spray in under these conditions. To reach these pressures, they use an electric lift pump to pump fuel from the tank to a mechanical pump on the engine, running nearly 3000 psi of fuel pressure in some cases.

Stratified combustion takes this one step further, and direct injection does not mean it also has stratified combustion. Stratified combustion engines are designed so that at TDC, there is a small pocket of air that is highly turbulent. The fuel injector sprays fuel into this small pocket and the charge motion causes the fuel to atomize very well, but limits the fuel movement to that charge pocket. The spark plug ignites this mixture and as the piston pulls away from TDC, the remaining air is mixed with the mixture that is burning. The results are an engine that can run at incredibly lean AFRs that would be otherwise impossible as the AFR has to be within an allowable range to ignite. If you've ever tried to "lean burn" tune a gas engine, you'll know what I mean. If AFRs go much leaner then about 15.5:1, it starts getting difficult to reliably ignite the mixture and misfires start to happen. Get around 16.5:1 and it starts getting incredible hard to light the mixture.

Stratified combustion solves this problem by creating that local pocket of air and fuel that is at much richer mixtures so that it can easily light it. Once it's lit, there is enough heat in the chamber to sustain the ignition event while the additional air is mixed in. That paper talks about this very subject and shows that once a "flame kernel" is established, the chance of the flame front dying drops to almost nothing.

The direct benefit isn’t the actual leaner AFR. All that really means is you have to increase the amount of air introduced for a given power output requirement. Simply put, you have to burn X amount of fuel to make Y amount of power if efficiency remains the same. More airflow however means lower pumping loses as the throttle is open more for that power output. Also, that pocket of air that is swirling is very efficient at combustion because it is so turbulent. Not only is it efficient at burning, but they also design the pocket so that there is a layer of air surrounding the pocket that basically helps insulate the burning mixture from the piston and chamber walls, which means more heat goes into the combustion event, raising flame temperatures and higher combustion temperatures generally mean higher overall efficiency. It also means less heat goes into the piston and head. Thus, the stratified combustion improves combustion efficiency and the lean overall AFR reduces pumping losses.

But due to the limited amount of fuel you can inject into that pocket of air, it also means you can’t get a ton of power out of stratified combustion and thus it is only applicable during low load conditions. Under heavy load, the injector has to fire off earlier and the entire charge gets fuel. The down fall is that you have now created two separate combustion areas that either can likely result in detonation and cause detonation in the other. Generally, you want to localize the charge as best as possible and keep it as close to the plug as possible. The further from the plug, the more likely it is to reach the auto-ignition point before the flame front reaches it.

This is why detonation almost always shows up first at the ring lands. It’s the furthest point in the chamber from the plug."

If you enjoyed this informative article, be sure to check out more of enginebasics.com engine related articles by using the links in the article, or found at the top of the page. Also follow us on twitter or facebook.

ATTENTION READER:

If you enjoyed the information and article you just read be sure to check out our newly released book with even more exciting photo's and information:How to Turbocharge and Tune your Engine

Want to know more about your particular Make and Model vehicle? All of these vehicles are covered in the tech, maintenance and repair articles found above. Enginebasics is the wiki or wikipedia of car part, repair, how to and tuning information. Let us be the class 101 for your automotive learning.

| Ford | General Motors GM | Pontiac | Jaguar | Land Rover | Nissan |

| Toyota | Honda | Lexus | Acura | Lotus | Scion |

| Infinity | BMW | Mercedes | Mitsubishi | Ferrari | Maserati |

| Lamborghini | Volks Wagen VW | Saab | Audi | Hyundai | Kia |

| Subaru | Mazda | Chevy | Volvo | Caddilac | Dodge |

| Chrylser | Daewoo | Porsche | Mercury | Freightliner | MG |

Individual Models

| Ford Mustang | Mitsubishi Eclipse | Mitsubishi Evo | Subaru WRX / STI | Dodge Viper | Chevrolet Corvette |

| Nissan Skyline | Honda S2000 | Nissan 350z | Toyota Supra | Chevy Camaro | Lotus Elise Exige |

| Honda Civic | VW Golf | Dodge SRT-4 | Eagle Talon | Acura Integra | BMW M3 |

| Nissan 240sx | Porsche 911 | Acura NSX | Honda Accord | Toyota Camry | Toyota MR2 |

| VW R32 | Dodge Truck | Mazda Rx7 | VW Jetta | Sand Buggy | Nissan Sentra |

For the latest Automotive news and stories visit the websites below |

Our feature Build: An AWD V6 Civic